Electric System Wrenches

Battery system wrench YS-e wrench

High tightening functions like torque control, angle monitoring etc., inherited from Yokota air operated system wrenches, are realized even by battery operated ones..

- Working efficiency improvement by wireless technology

- Simplification of installation and relocation

- Clean & Silent

- Low vibration and Low reaction force

Workability Improvement by such design as compact, light-weight and more quiet

No need of power cord (air hose or power supply cord) and signal cable owing to the battery operation and

wireless communication. Simplification of installation and relocation owing to the saving of wiring harness

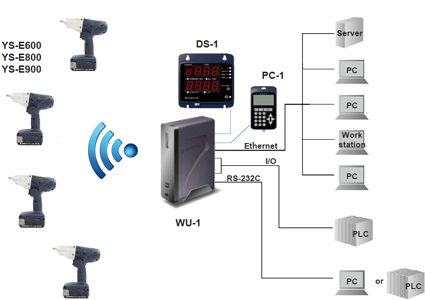

System configuration

• Possible to connect 4 tools with the wireless unit

• WLAN communication between tool and controller

• Poka Yoke compatible

• Traceability tightening data

• LAN and RS 232 interface

• I/O terminal for input and output signals

Features YS-e

- Strain gauge and direct current detection system make the tool compact and weight saving

- Low vibration, low noise and low reaction force due to the direct drive

- Built-in controller and driver functions

- Built-in buzzer/LED inform an operator of tightening result and abnormal tightening

- Battery with remaining capacity display adopted.

- Tool Protector with different color by model

- Applicable capacity : Line-up to M5-M10 (5-50Nm)

Electric System Wrenches (e-M wrench series)

Electric System Wrenches (e-M wrench series) are torque controlled tightening tools with commercial electric

power source AC100V-AC240V.

Torque controlled tightening system with highly accurate torque output.

Upper and Lower limits torque assurance for the critical joints.

Auto stop

Bolt number management

Built-in electronic buzzer or LED

Data management of torque value

Lineup covering bolt capacity range:M5-M12 (Torque adjustable range 3.0-90 Nm)

Pistol type

e-M500 ,500- S , 500-A

System E-wrench

e-M700 , 700-S

System E-wrench

e-M900 , 900-S

System E-wrench

e-M1100 , 1100-S

System E-wrench

Air System Wrenches Torque control and Angle monitoring

High accuracy

Product liability is essential to car manufacture. All tightened joints have to be correct. For this reason critical joints must be counted, documented and, of course, tightened with the right clamping force. In order to do this, you need an impulse wrench (with a built-in transducer) connected to a controller. This system ensures that only OK joints are counted resulting in "Zero Fault Production". This fail-safe system fits perfectly in the Poka Yoke Strategy.

POSSIBLE ERRORS

• Detection insufficient torque and over torque

• Detection friction coefficient out of tolerances

• Detection of too long / too short bolt

• Detection of seizure

• Detection of cross threaded threads

• Detection of crooked threads

• Detection of damaged threads

• Easy to program, according to application specifications

• Easy to program with PC

• Torque calculation over several impulsions

• Compensation impulses to compensate the relaxation (soft joint)

• Poka Yoke proof, line management

• 2-step tightening optional

• 8 setting programs

• Parallel and RS-232 connectors standard 2-way communication through RS-232

• Automatic program change (sequence programmable)

• Real time clock

• Build-in timer for group control

• Several input signals

• Several output signals

• Statistics inside CP / CPK

• Memory for 10.000 cycles

• Transducer integrated, direct measurement

• Angle encoder integrated

• Compact angle encoder

• Torque transducer non - contact type

• Torque - and angle curve on PC

• Easy torque adjustment on the tool

• LED or acoustic signal on the tool

• High efficiency air motor

• Shut-off by external solenoid valve

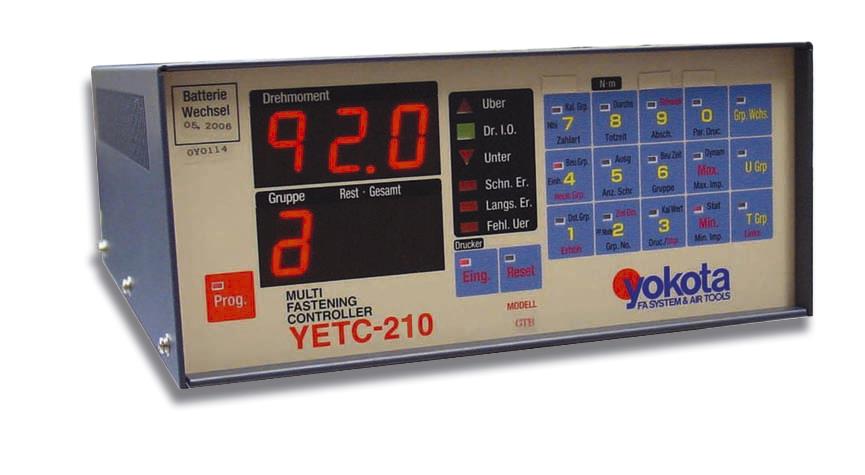

TKA SYSTEM

Angle monitoring

YETC-230ER

YOKOTA Controller

YETC-230ER-L

YOKOTA Controller

YETC-330ER2-L

YOKOTA Controller